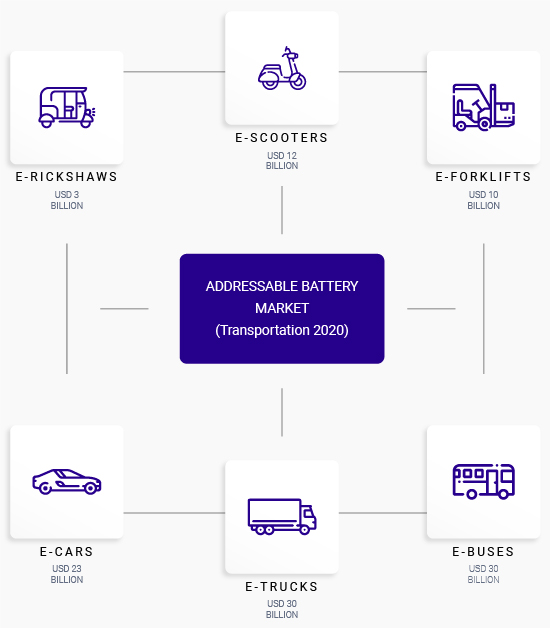

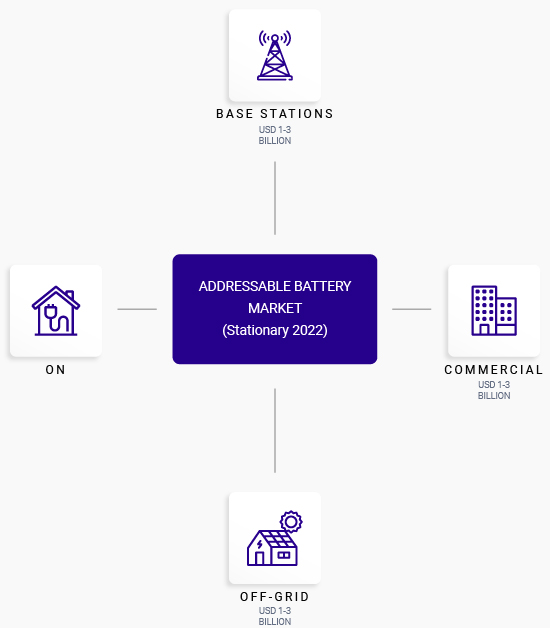

Market Size

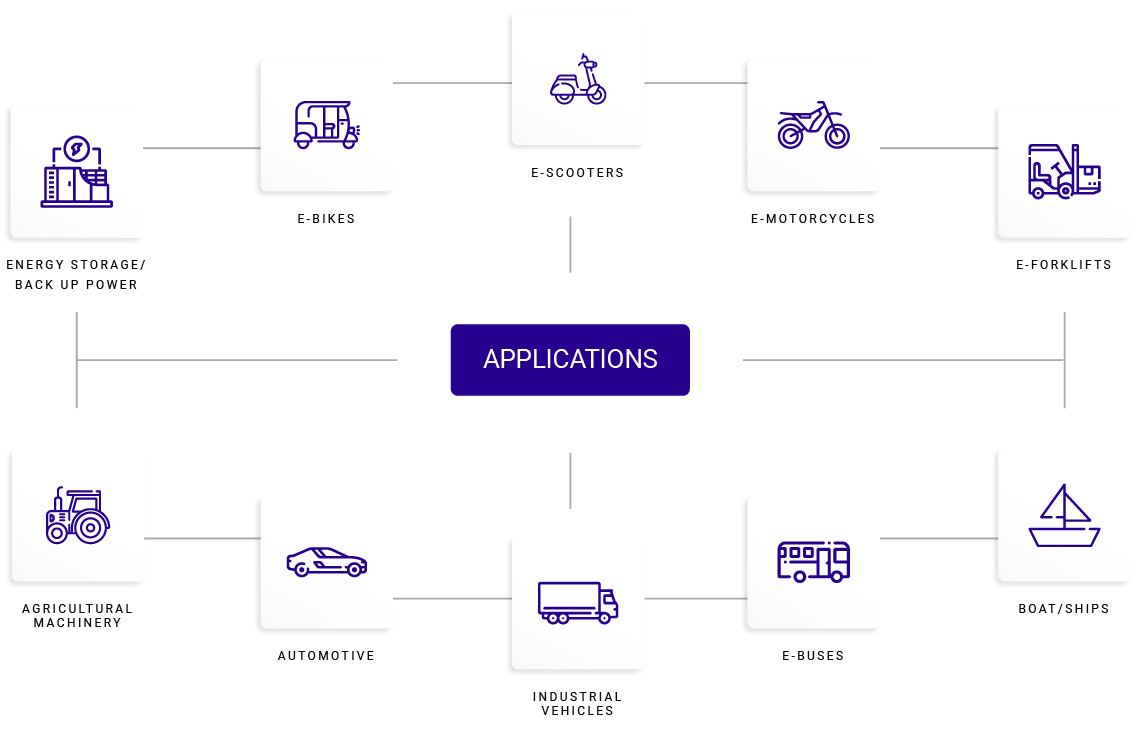

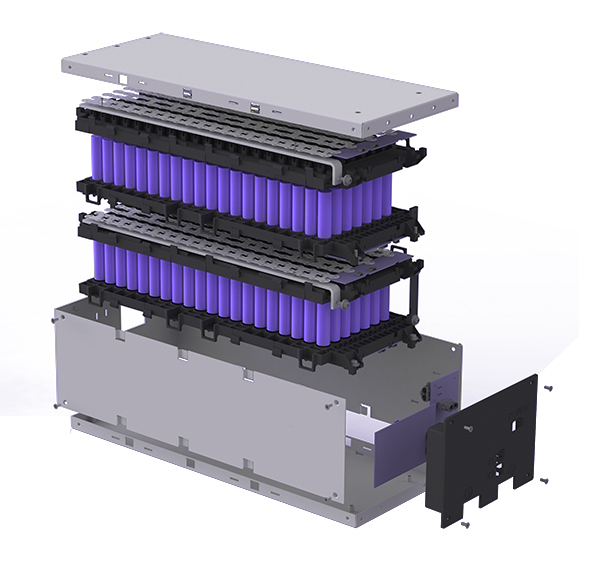

The Addressable & market size is increasingly on the rise & is expected to expand many folds in the coming years. It has become a race to not only build capacity but to also continuously innovate in the Material Chemistries & typically the Cathode Materials. The applications known today may be redundant tomorrow with newer chemistries being explored by peers globally. The goal is not only to build a company to stay ahead of the curve but to also innovate new chemistries to ultimately reach the tipping point or the so called ‘Holy Grail’ in battery chemistries.