Tool Room

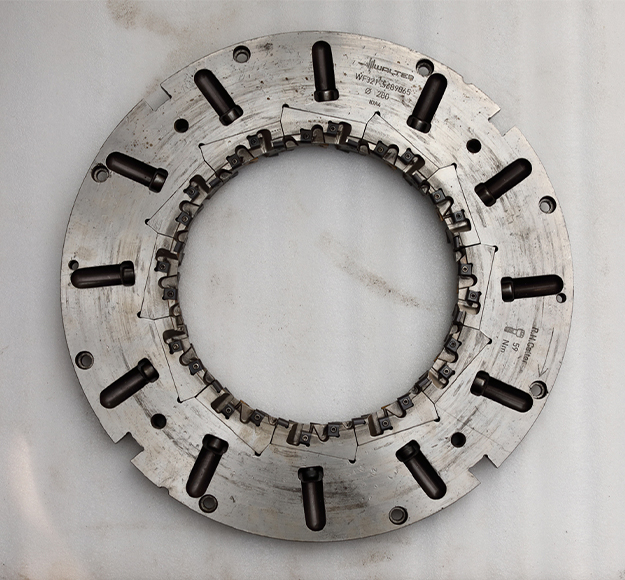

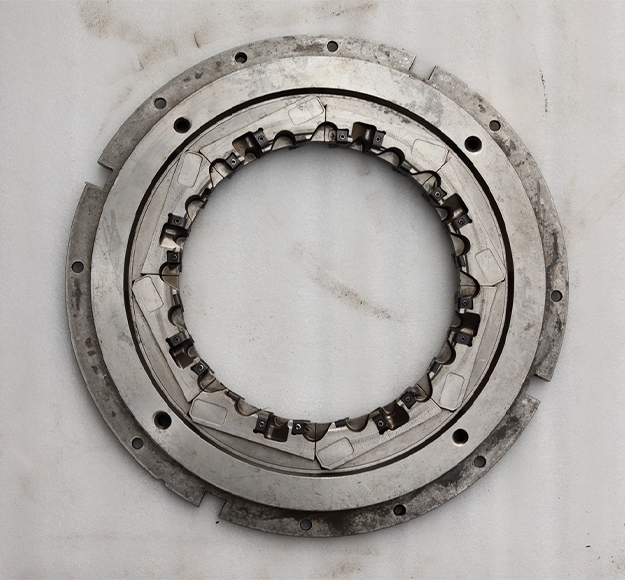

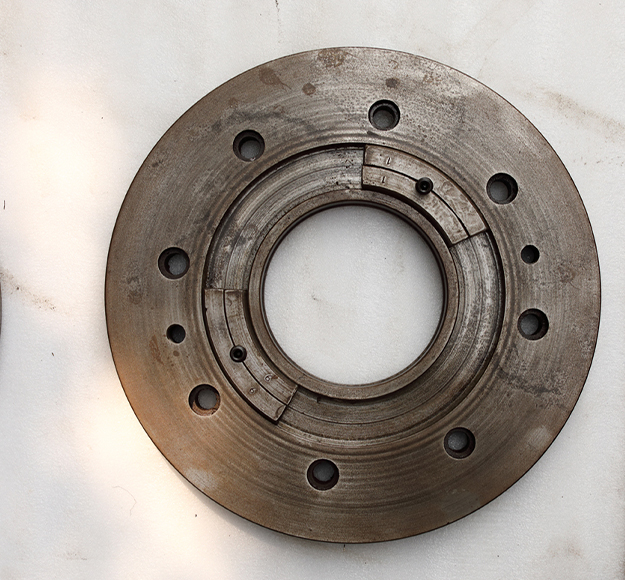

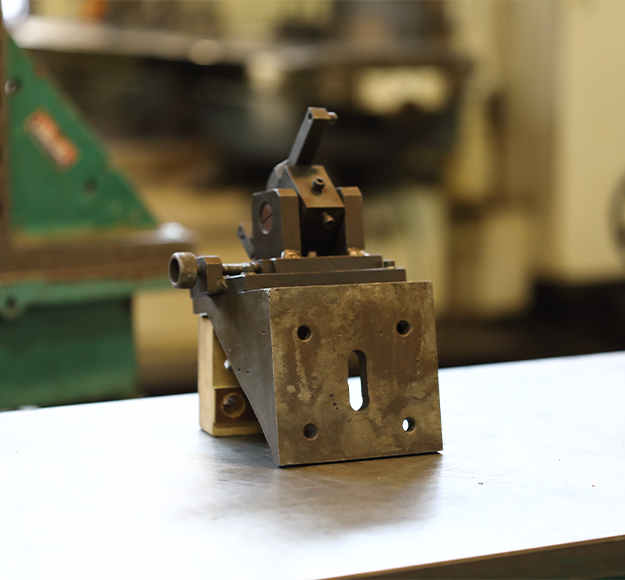

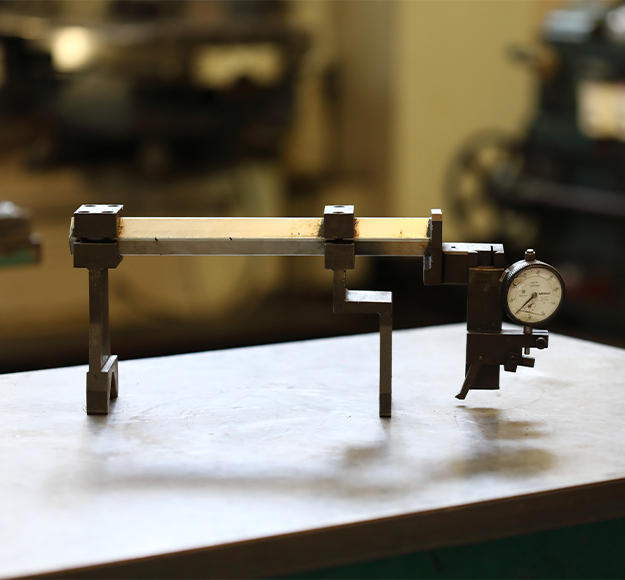

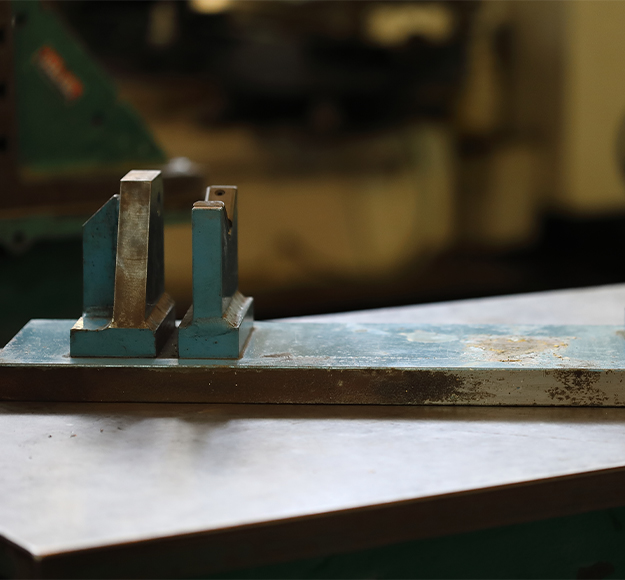

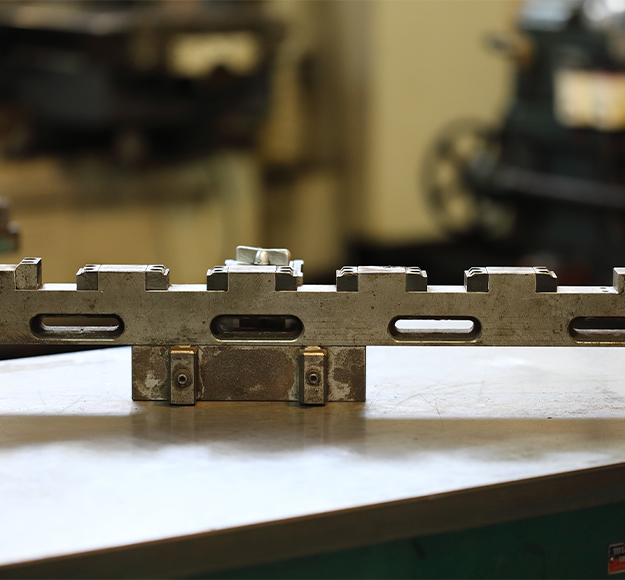

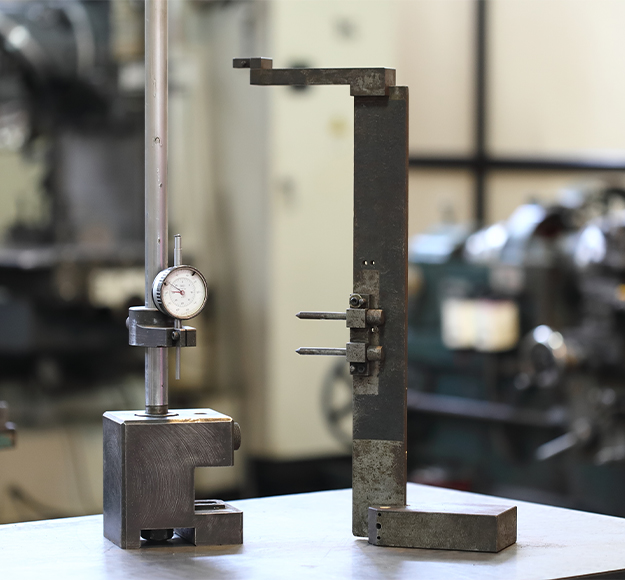

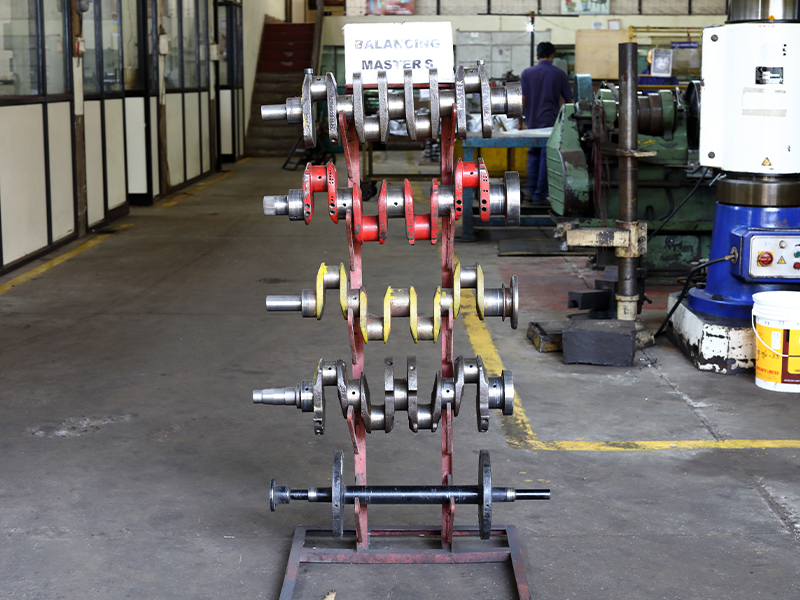

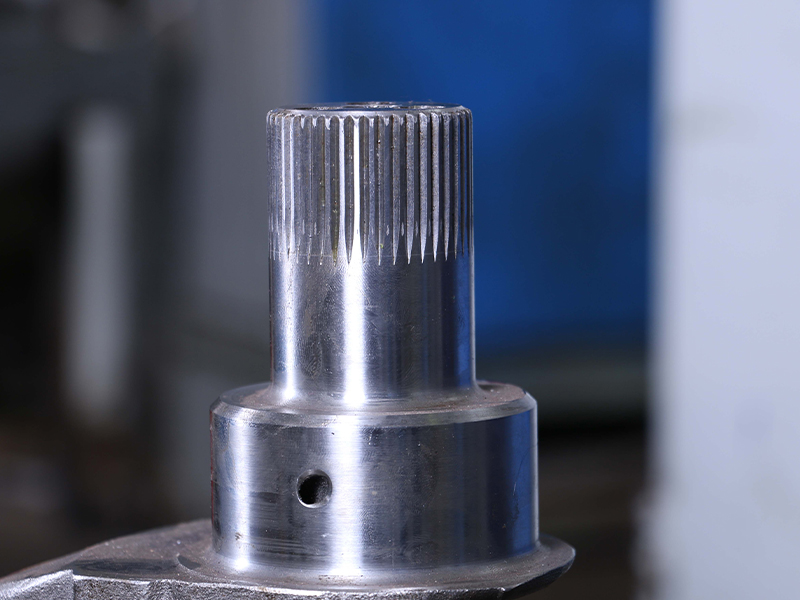

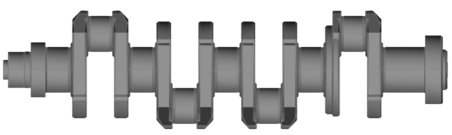

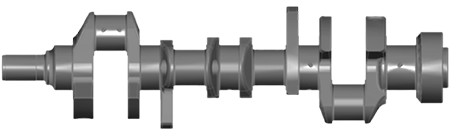

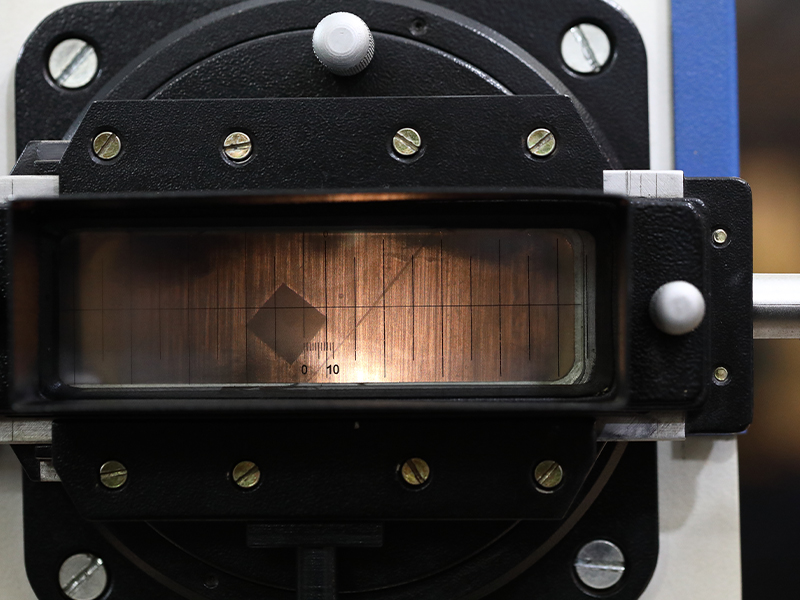

All the required Toolings are produced in our comprehensive In-House Tool Room. The same is key to manufacturing flexibility & adding speed to Production. We have a fully integrated Tool Room & all Jiggs, Fixtures, Coils, Forging Dies & related toolings, etc. are produced In-house. This enables shorter lead times & also enables us to have minimal breakdowns in our production lines on account of Toolings.

We have also introduced 3D Printers in our Tool Room to further add flexibility & speed up our Tooling Process. We presently have one of the shortest Tooling Lead Times in the Marketplace credited to the said infrastructure.

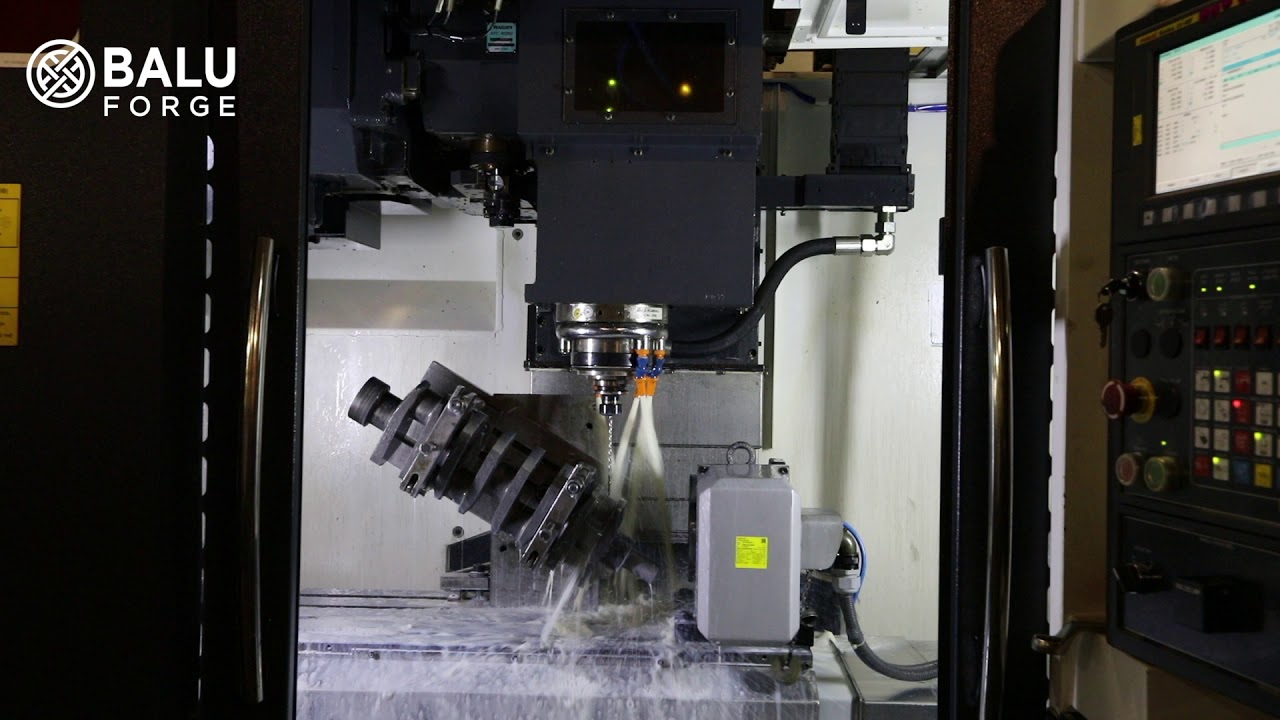

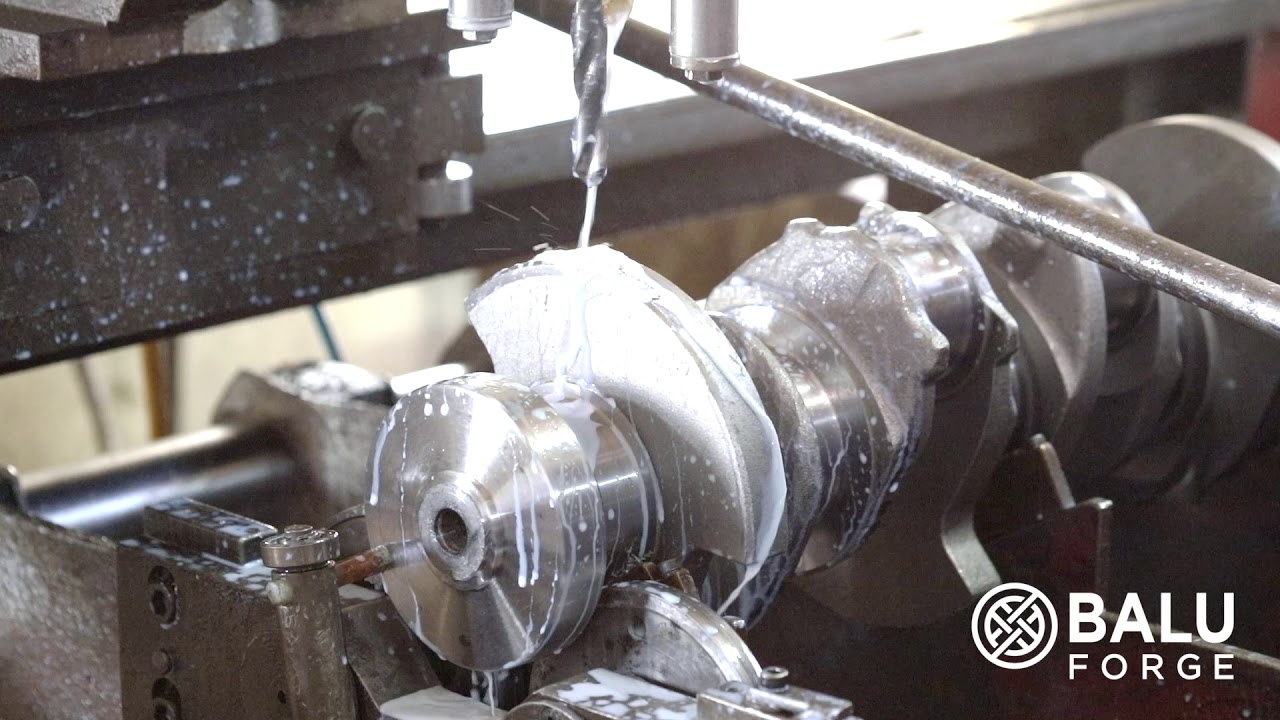

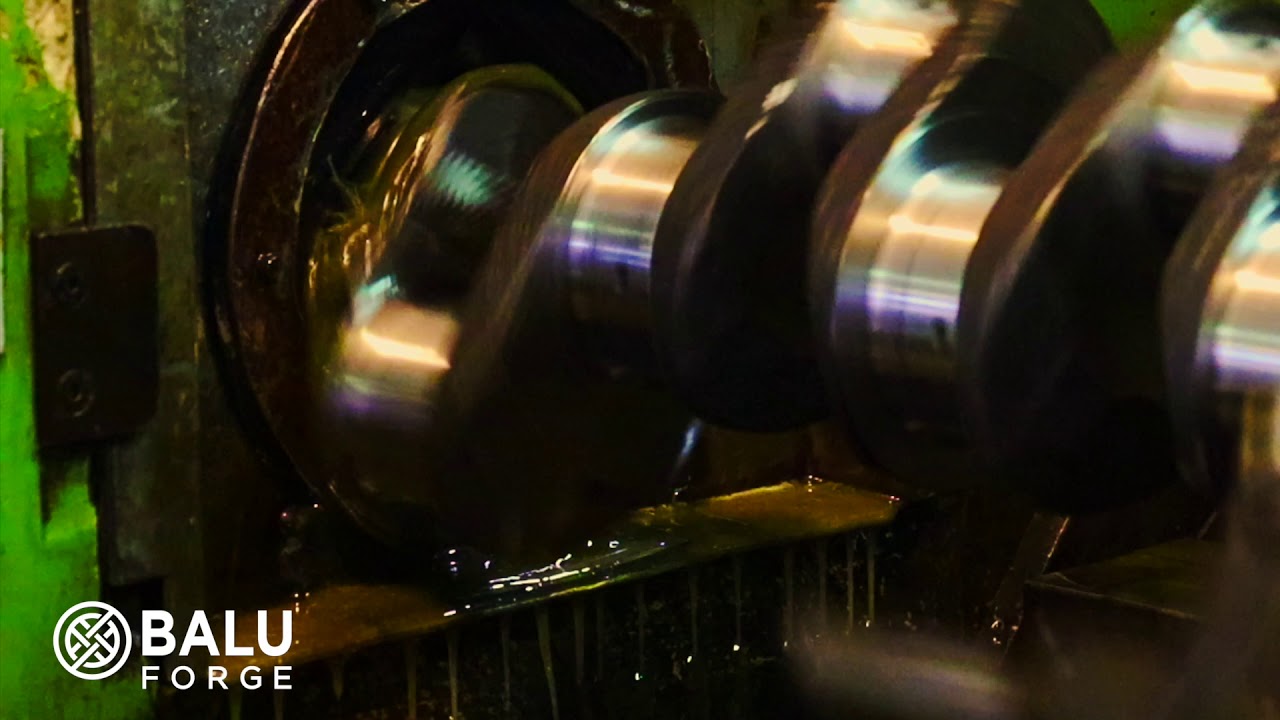

Our Forging & Machining units are completely integrated with our own In-House Die Making. This offers greater flexibility & shortens our lead time for New Part Development. All Die Blocks are sourced from reputed manufacturers with no compromise on quality & offers greater Die life for our production.

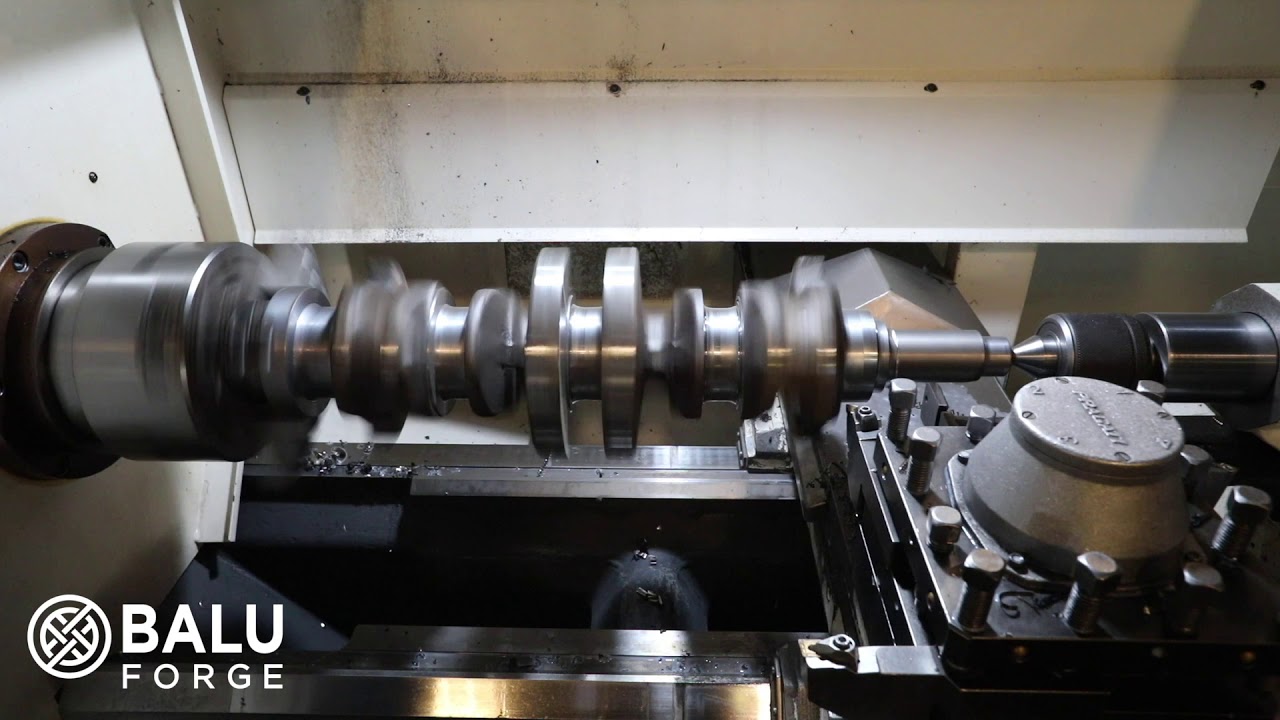

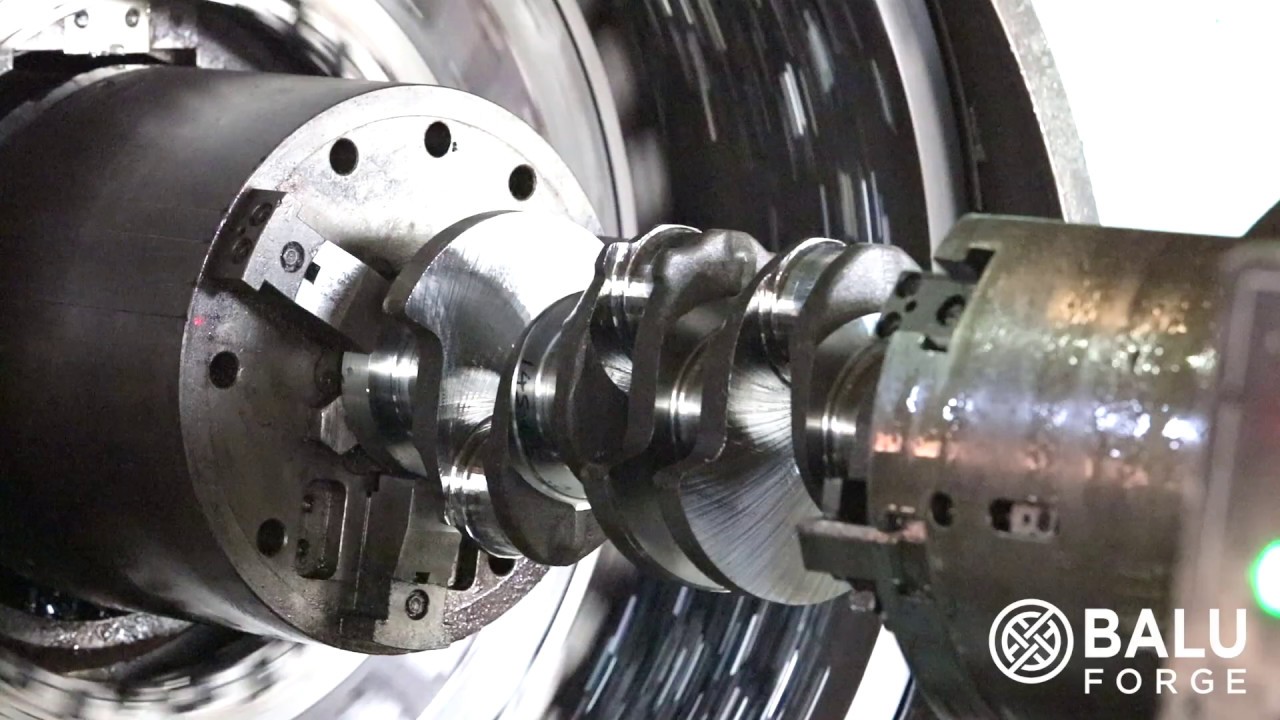

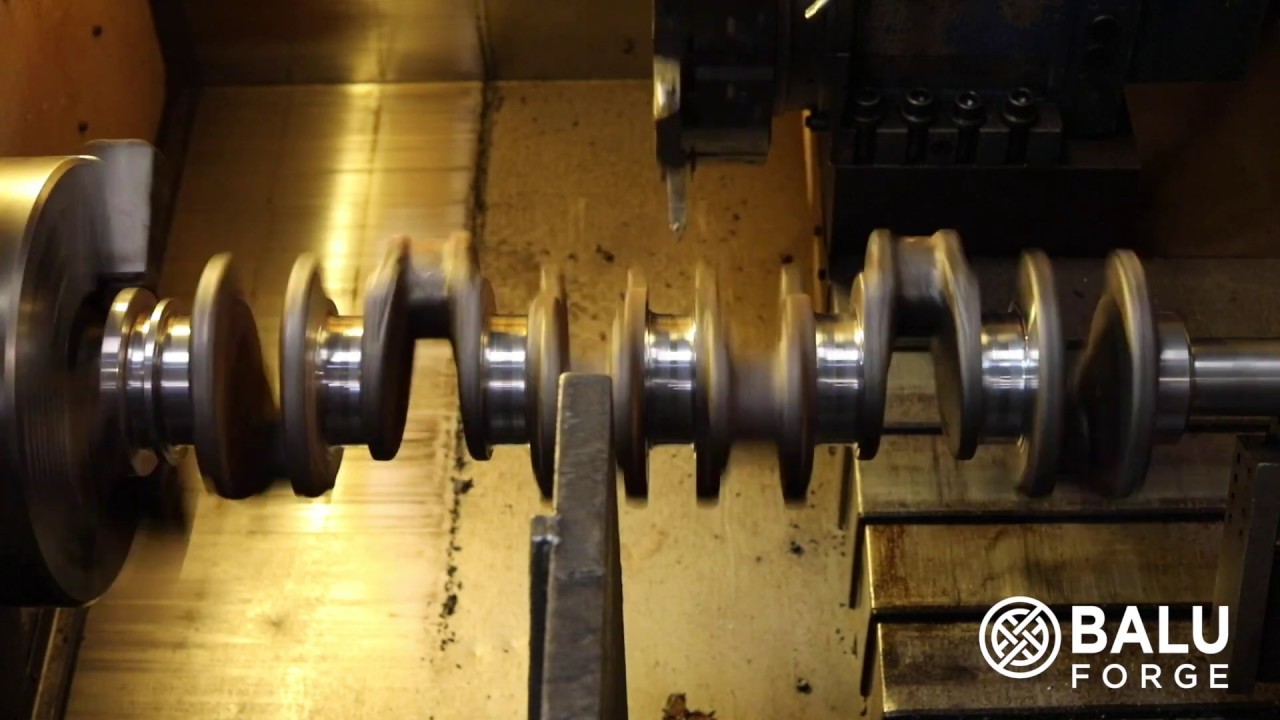

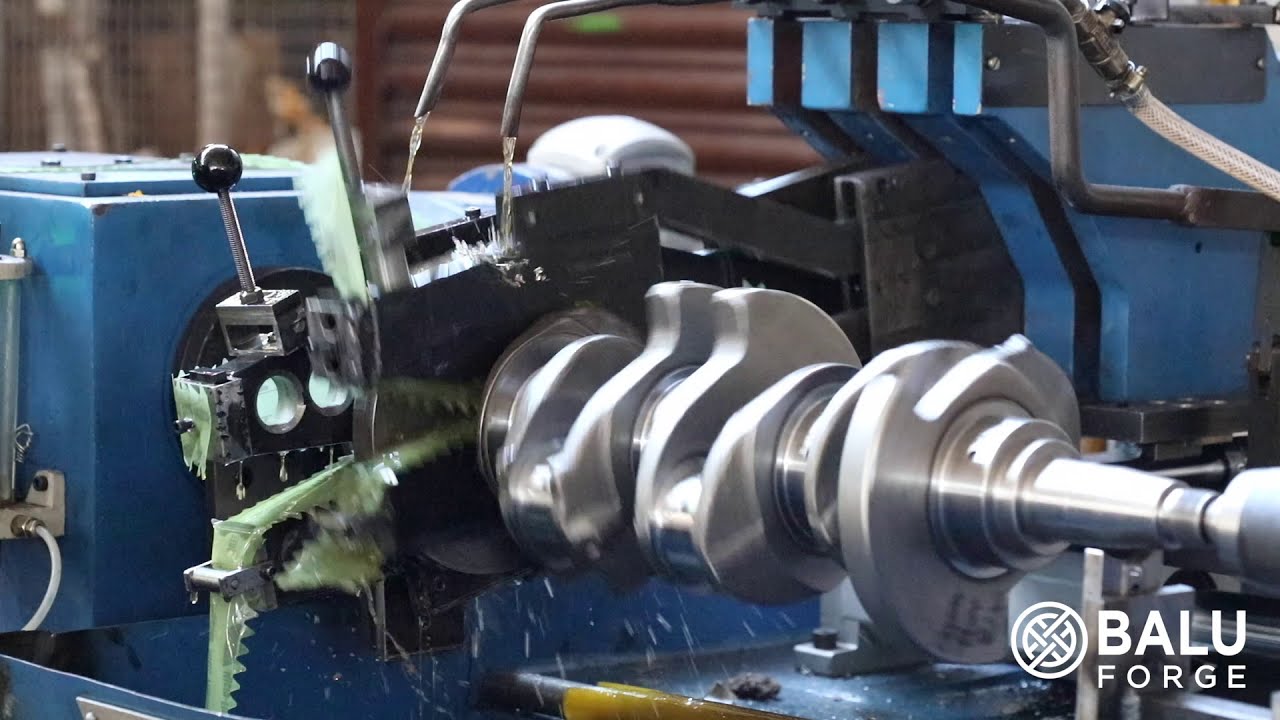

Watch video